Overview

Kobe Steel, in its Ohio mill, took advantage of a uniquely designed steel transfer car manufactured by Handling Specialty. The extreme-duty car was required to accumulate wire rods continuously and then transfer them between process lines. Two traversing Transfer cars, with power-clamp tooling for handling the wire rod, were designed and constructed for a new product assembly line. Essential to the success of the application was the cars’ durability: They needed to withstand the harsh manufacturing environment of a steel mill as well as endure continuous cycling. The 13,000 lb. capacity car had a self-propelled system which incorporated specialized hydraulic and electrical components.

Features

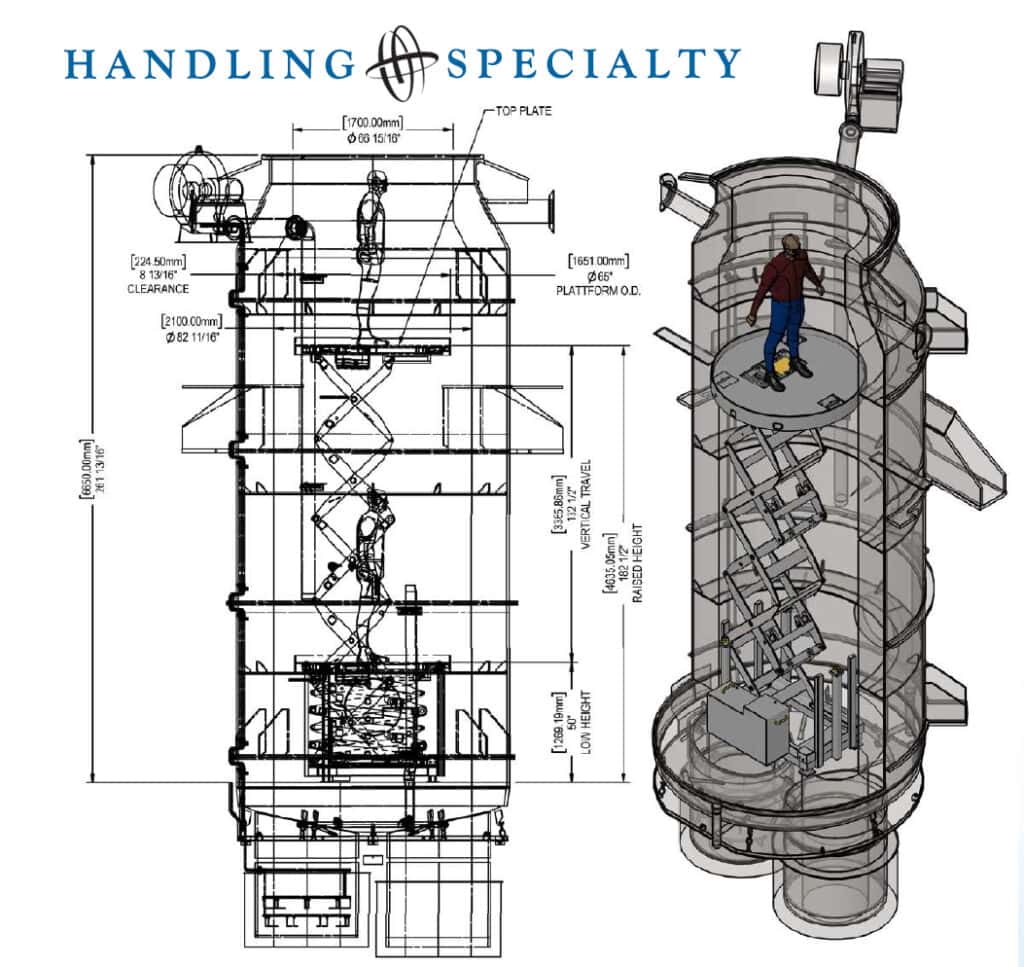

- Heavy duty scissor lift.

- Traversing transfer cars with power clamp tooling.

- Continuous running cycle, extreme duty conditions.

- The rugged system was built to withstand the harsh industrial environment in a steel mill.