Ladle Rebricking / Relining Platform

Ladle Lifts

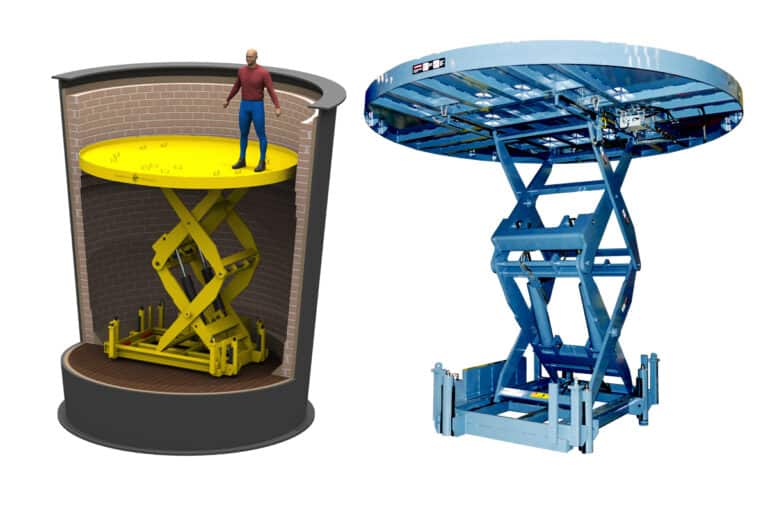

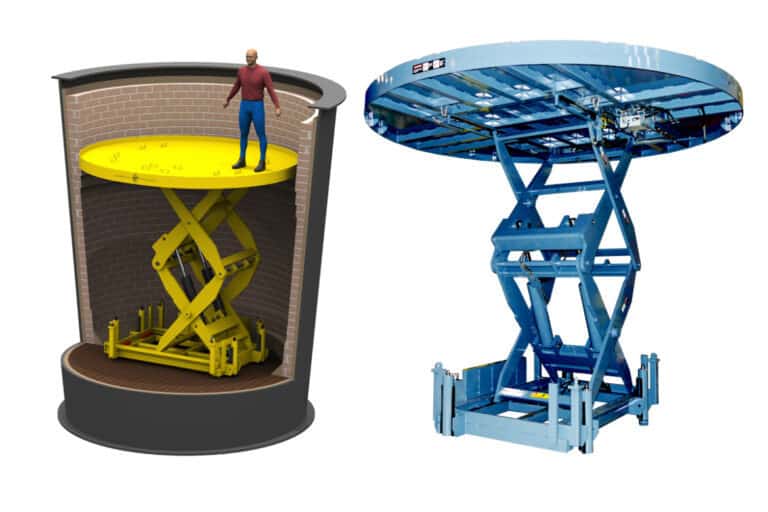

An upgrade to traditional scaffolding, the ladle rebricking platform allows for easy and safe replacement of refractory bricks.

| Solution: | 8821 |

| Industry | Iron & Steel Industries Manufacturing Equipment |

| Type: | Multi Stage Lift |

| Actuation: | Hydraulic |

| Capacity: | 10000 |

Overview

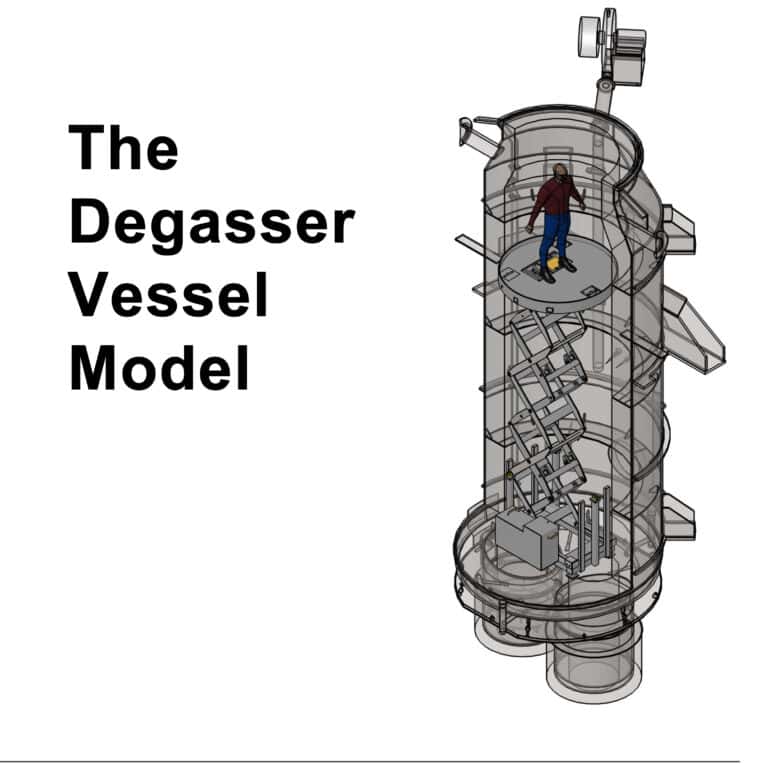

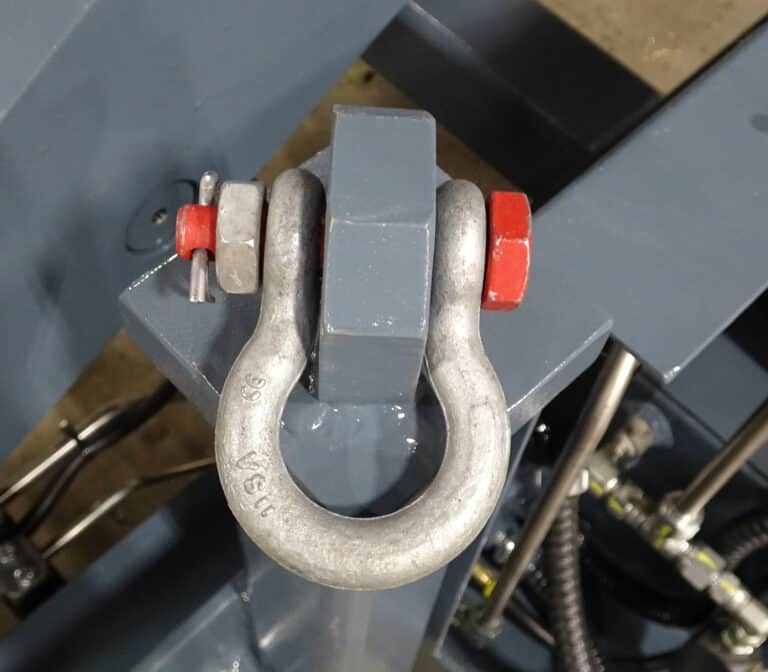

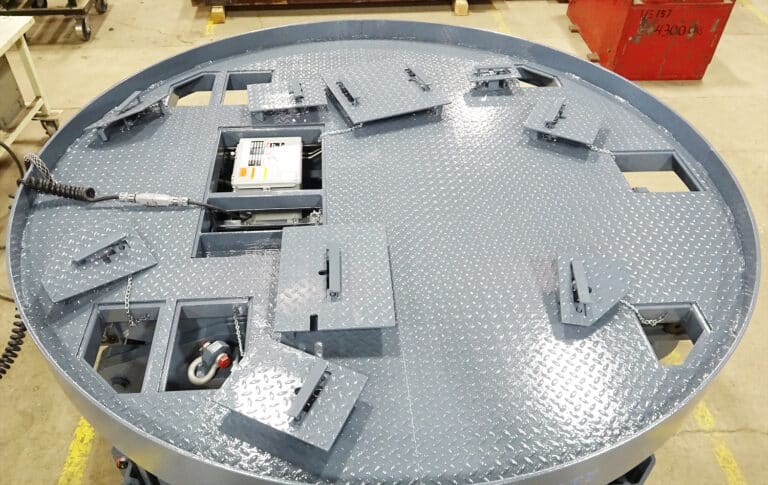

Ladle rebricking / relining platforms have replaced the traditional scaffolding used in the re-bricking process at many steel foundries as a safer and more reliable option. Refractory firebrick in pour ladles requires continual replacement, and the Handling Specialty ladle lift was designed as the perfect solution. The lift is loaded into the ladle using a crane and can be moved to the next ladle, requiring re-bricking. These two-stage scissor lifts are designed to withstand harsh melt shop environments, improving efficiency in the factory.

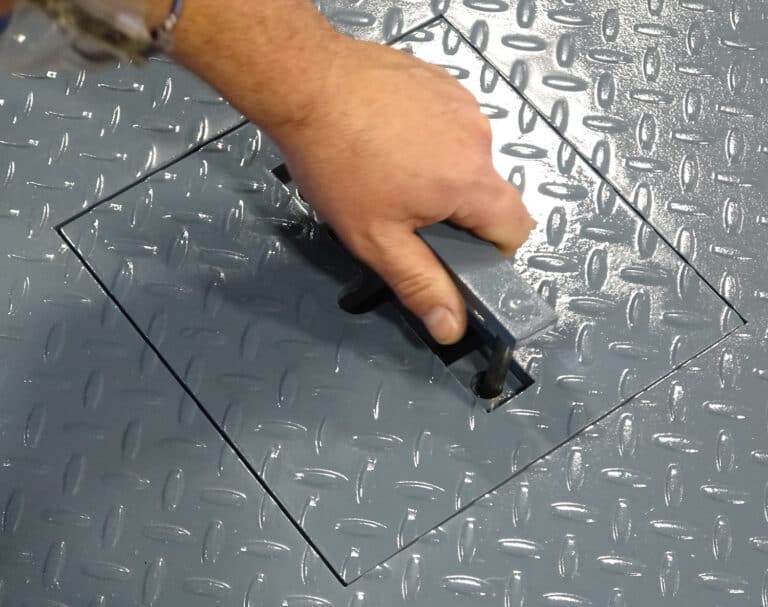

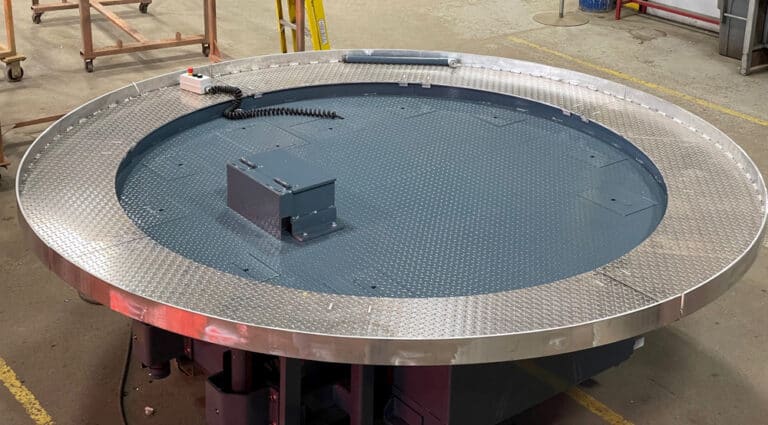

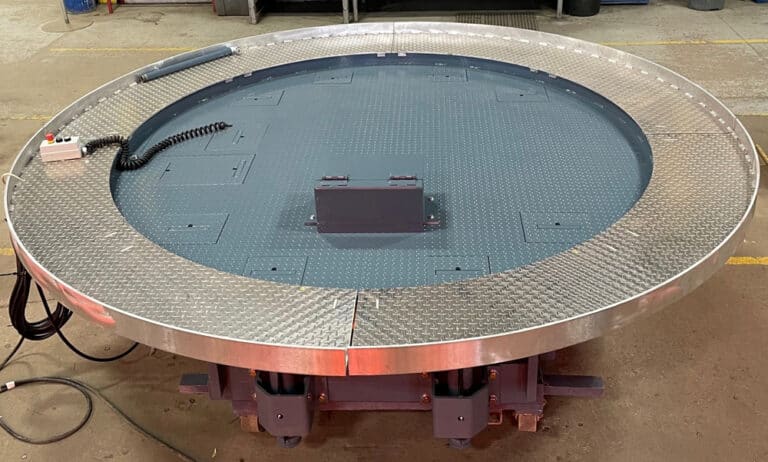

This custom model also includes three sets of aluminum extensions which connect to the lip along the outside of the platform. Each extension allows larger ladles to be re-bricked, whether oval or round.

The heavy–duty scissor lift raises and lowers the operator and bricks via a hand-held controller for easy operation while handling heavy loads.

Gallery