Overview

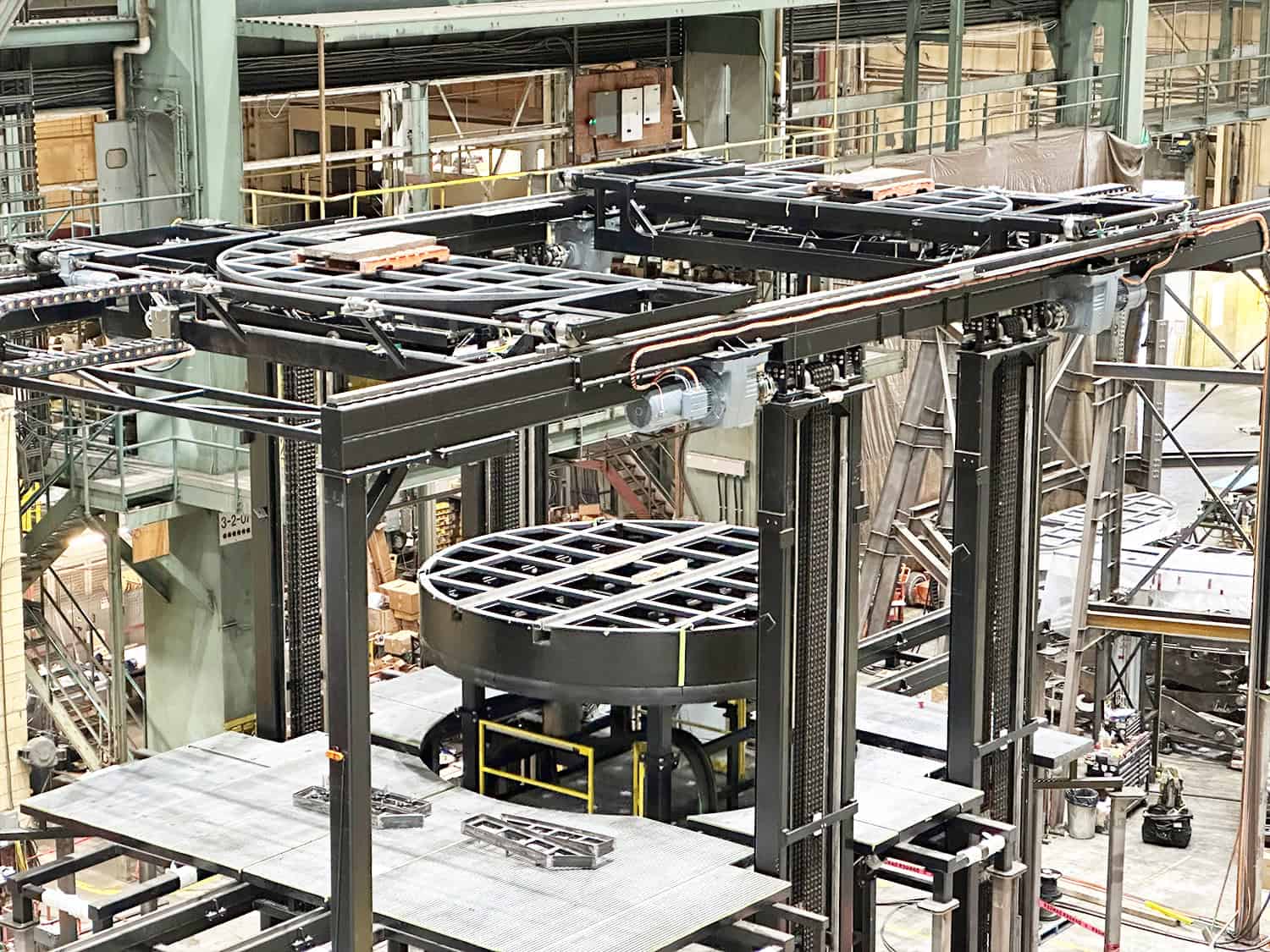

This custom, circular stage lift system was designed and built to the specific requirements of a theater company’s choreography at their themed resort. As are many of Handling Specialty’s custom equipment packages, this was engineered as a turnkey solution for their spectaculars. Included in this design were two self-propelling Sloat lifts to travel in and out of the central stage area, one central, circular lift system including water dam and seal, and one super structure and staircase access to center lift pit. This project is the result of a long and exciting partnership with this theater company. Handling Specialty installed and maintains all of the equipment supplied.

Features

SLOAT SYSTEM

The “system” consists of two self-propelling carriages, each with a scissor lift on board and a semicircle top platform complete with Mondo Flooring.

The system has all the supporting steel to accept loads down to the basement floor and supports the traversing rails that will guide the Sloat lifts from off stage to the center opening location.

Cable Track and cabling for the Sloat lift and traverse were included. The cable track was oversized to allow for future expansion of EFX.

Encoders were employed for control of traverse and lift.

Lift is powered by external hydraulic power unit located in mechanical room.

Traversing action is via an electro-mechanical, gear motor.

Support steel has load plates for affixing to the basement floor.

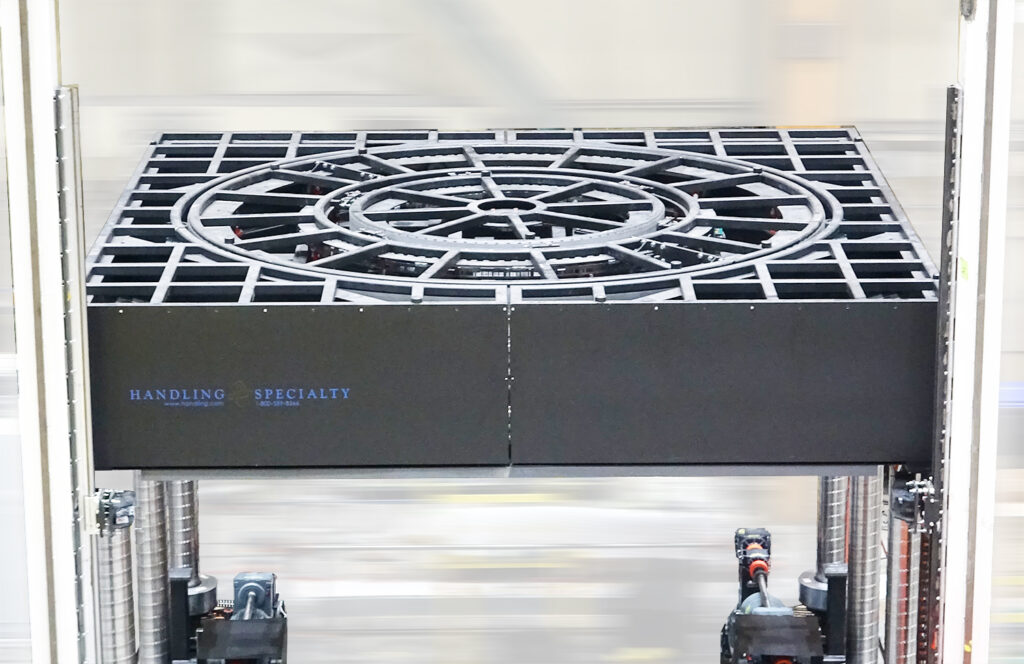

CENTRAL LIFT SYSTEM

One center lift covered with Mondo flooring.

Each of four columns has its own electro-mechanical drive.

Electronic synchronization is employed to ensure reliable level lifting and system repeatability.

The columns also interface with the Sloat support steel to achieve an overall rigid network.

A “loop” system for both the electrical and water management from source to lift.

All columns come with bracing and base plates and levelling bolts.

The DAM

This element forms the center opening of the stage floor.

This is a fabricated beam structure, approximately 19′ in diameter.

Contains an inflatable seal which forms a water-tight seal between the stage floor and center platform.

CENTRE LIFT INFILLS & STAGE LOADING “T” TRACK NETWORK

Center pit infill, tracks.

The infill flooring is a composite material with steel superstructure underside.

“T” Tracks (one on south side and one on west side) will be provided on-stage and off-stage for the load on/off of the Aquarium and other large-scale scenery or acrobatic elements.

Pit stairs provided.