Overview

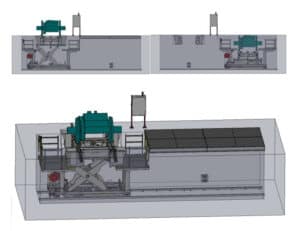

Our rail equipment dealer received a purchase order for one 25-ton Drop Table including a traction motor dolly, locking bar pockets, packaging and freight, installation, commissioning, and training. This Drop Table system will be used to remove and re-install wheelsets on freight cars.

Drop Table:

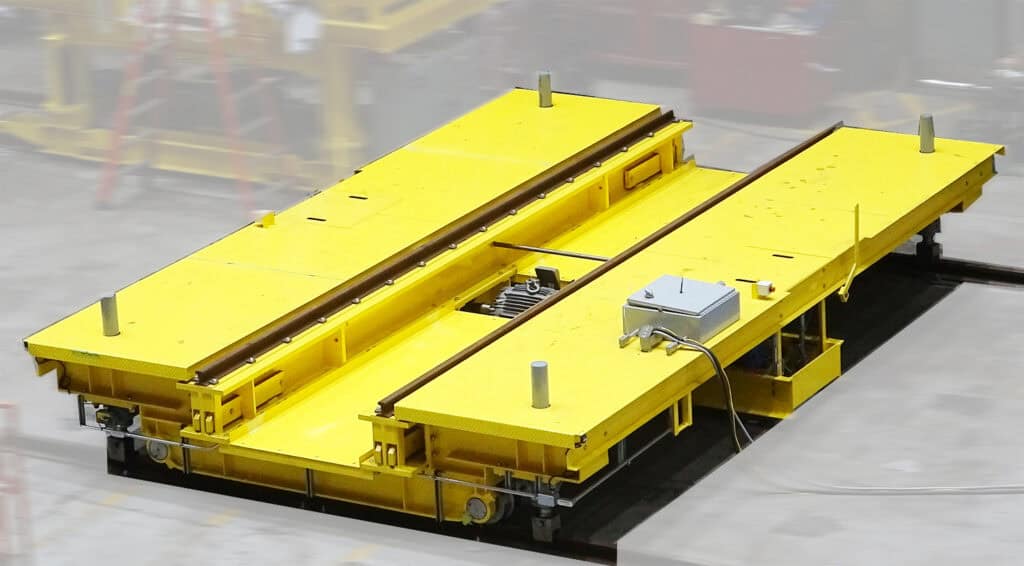

The main drop table trolly uses an HPU to power the scissor lift as well as the traverse motor. The Scissor Lift is used to elevate/lower the Service Top in the Service area and the Release area. The scissor lift is hydraulically powered and is installed on the Trolley. The Scissor Lift Platform has four (4) guides that will locate the Service Top to the Scissor platform. The Trolley is a mobile cart that traverses the pit on floor-mounted rails. The trolley consists of three main areas. The Scissor Cradle is a structural framework that provides mounting interfaces for the Scissor Lift. The “Operator Work Platform” has stairs to allow the operator to climb down from floor level safely. The “Operator Work Platform” has a full-size handrail. The platform is rated for 500 Lbs. (227kg) total capacity and is designated for personnel access to perform wheel removal and installing tasks.

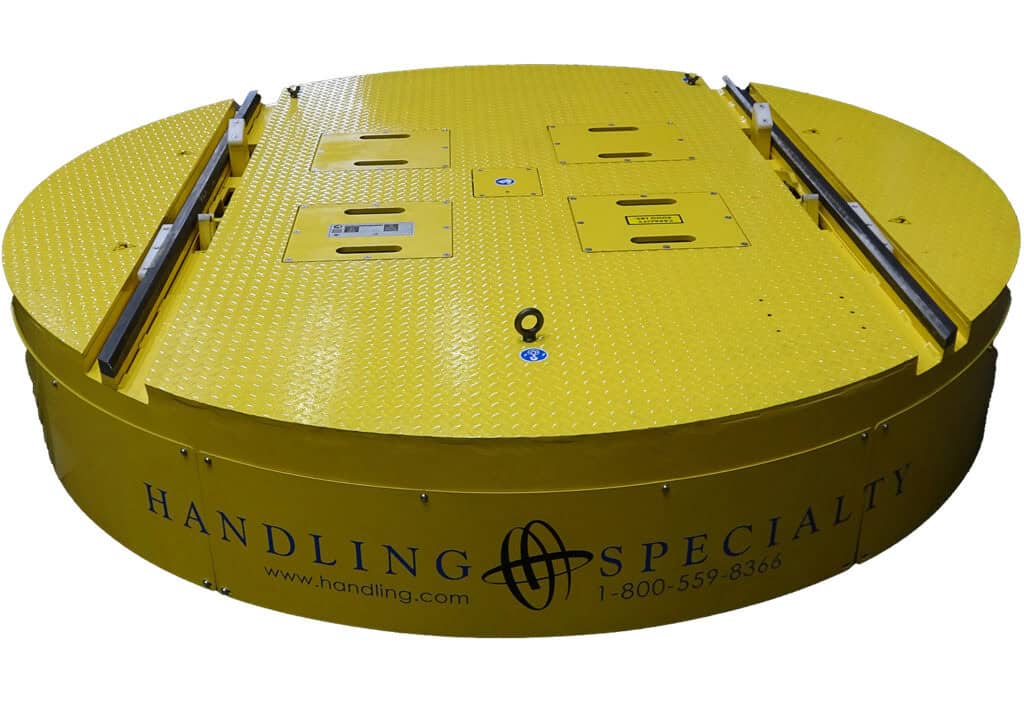

Service Top:

The Service Top is supported at track level in the Drop Table Pit by integral locking bars. By manually operating a lever connected to a linkage assembly, the locking bars are inserted into or disengaged from locking bar pockets installed in the pit walls at the service track location. With the locking bars disengaged, the service top and wheel set may be lowered by the lifting beams on the carriage. In operation, the carriage must be spotted under the desired service track or release position before the lifting beams are

allowed to be raised.

Traction Motor Dolly:

The Traction Motor Dolly, when used in conjunction with the Drop Table, can facilitate the removal of a traction motor, including wheel and axle, from a locomotive without removing the entire truck. The primary function of the dolly is to support the traction motor housing while it is being lowered from under the locomotive. The dolly is equipped with a hydraulic cylinder that is used to tilt the motor back to provide clearance between the motor lugs and the spring nest or bracket on the truck frame. With some locomotives, the traction motor cannot be removed without first removing the spring nests. In these cases, the hydraulic jack (with a manual pump) on the dolly is also used to compress the springs in preparation for spring nest removal.

Locking Bar Pockets:

Locking bar pockets consist of four (4) pedestals that will be mounted in the customer’s pit. Each pedestal will be installed and leveled using approx. 1” grout to align the Service Track Rails when it is in the raised position. Used in conjunction with the Trolley and the Scissor Lift, the Locking Bar Pockets allow for the removal of the wheelset and the transportation of the wheelset to and from the Service and Release track locations.

Features

- Lowered Height 55-1/2” (1410 mm) top of pit rail to top of service top rail

- Raised Height 103-1/2” (2629 mm) top of pit rail to top of service top rail

- Hand-held pendant

- Limit switches

- Emergency Stop