Overview

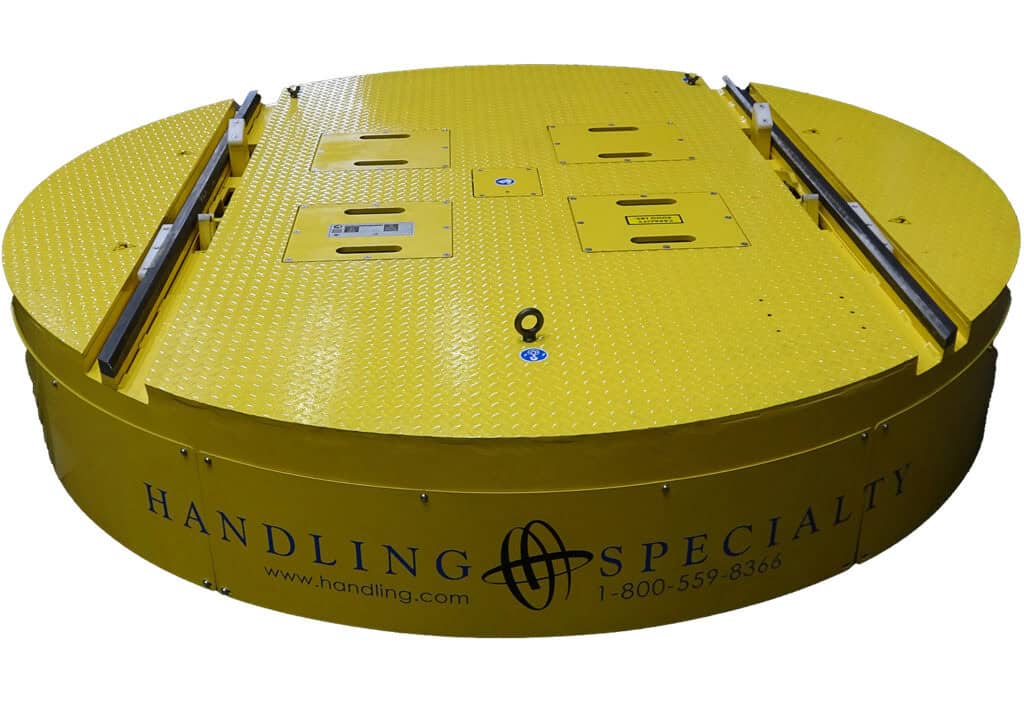

Handling Specialty’s rail car personnel platforms for Thrall Car Manufacturing were designed to improve productivity and, at the same time, relieve worker burden.

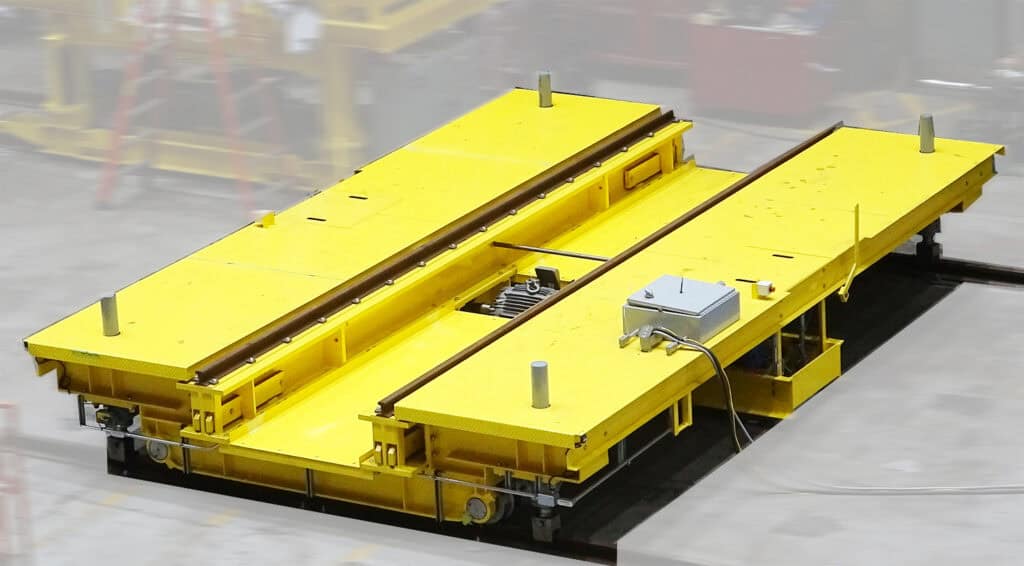

Thrall Car Manufacturing produces two railway cars daily for the transportation of automobiles. Metal screening on the exterior of the rail cars requires considerable installation and worker scaffolding. The Handling Specialty lift was designed to carry workers vertically and horizontally alongside the rail car, allowing them to work at any elevation. Travelling up and down more than 200 feet of track, the lift is automatically self-propelled.

With a capacity of 4,000 pounds, the lift is not limited in its “user-friendliness.” Features include an onboard full system control with auxiliary operator controls, rivet storage bins and automatic pick-up of power cables onto a reel. Safety considerations include a guard rail and kick plate system, as well as full bellows and a safety ladder with an electronic interlock.

The personnel lift is another example of how Handling Specialty’s solution-based engineering can improve productivity and increase worker safety.

Features

- Self-propelled.

- Lift elevates workers for the riveting of side panels.

- Carries workers vertically and horizontally along railcar.

- Safety features include a guard rail and kick plate system, full bellows and a safety ladder with an electronic interlock.