Overview

Handling Specialty designed and manufactured six (6) personnel lifts for an international locomotive engine manufacturer in the USA. The lifts are operated in pairs (with the engine in the center) and allow technicians to safely and ergonomically position themselves during the assembly process. In addition to the lift raising up and down, the platform is also equipped with five (5) sliding extensions that allow technicians to move closer to the engine. The extensions, which are controlled by an electric cylinder with a brake, are 35″ wide and can extend 21″, with a capacity of 300 lbs.

Various safety features were incorporated into this lift, including:

- The anti-skid finish on the platform and anti-fall protection are provided via a vertically mounted rack.

- The base has locking gates to prevent personnel from walking under the platform when raised.

- Edge protection via the touch bar on the edge of the extensions.

Features

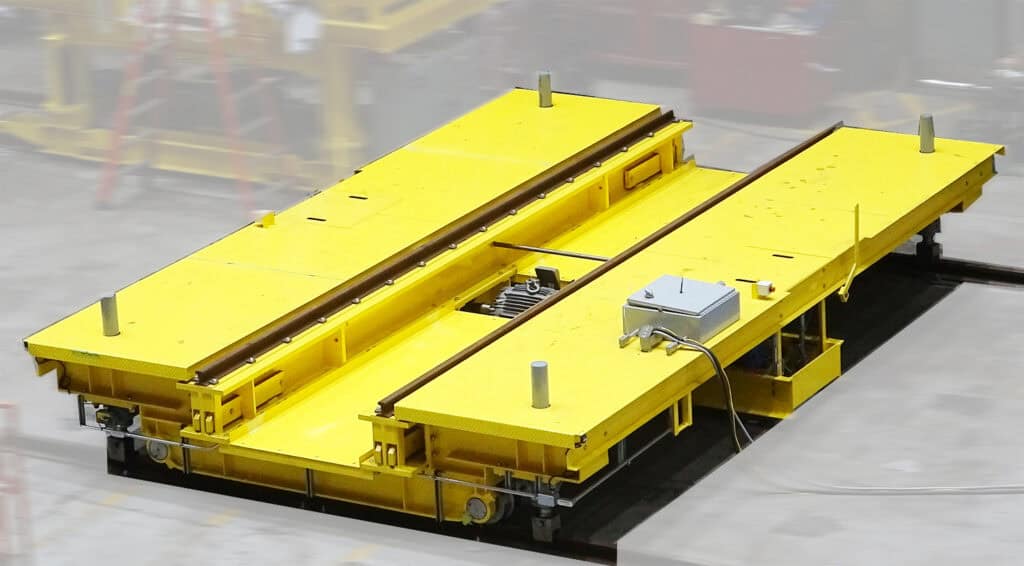

- 4,000 lb lift capacity, hydraulic actuation, 56″ x 190″ platform area, 61″ vertical travel (rise rate approx. 2″ per second); the platform includes five powered extensions to allow personnel to access the locomotive engine during the assembly process.

- Extensions are 35″ wide with a 21″ extension distance.

- Duplicate controls are located at either end of the platform for operator efficiency.

- Various safety features, including locking gates, anti-slip surfaces, anti-fall protection, and fail-safe operation.