Overview

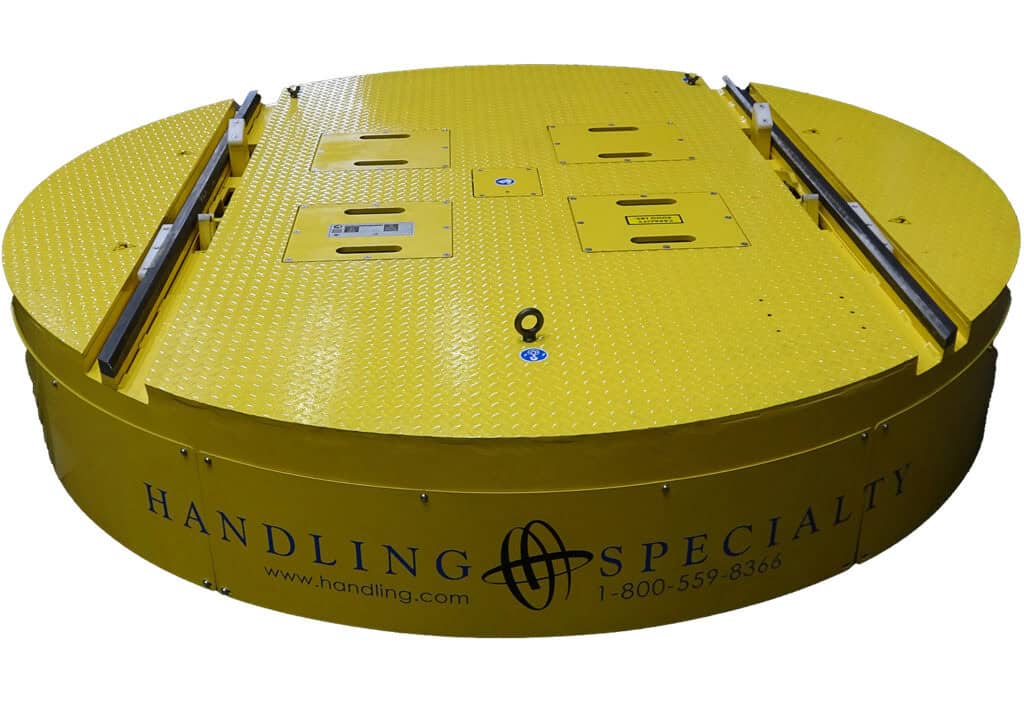

Handling Specialty was approached by a mining company to engineer and manufacture a heavy-duty, durable wheelset change-out system for railcars used in mining operations. The lift was manufactured to last in the extreme conditions that exist in mining facilities in northern Canada.

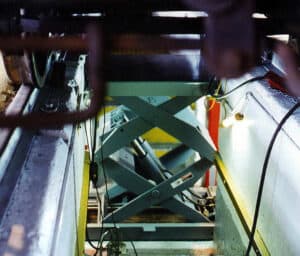

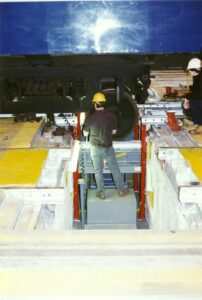

The wheelset change-out process begins with a train moving into the rail maintenance facility. The train is positioned with the worn wheelset over the split rail section of the track attached to the wheelset drop buggy. Once the wheelset is blocked into place on the lift, the split rail is then manually disconnected, allowing the buggy’s lift to hydraulically lower the wheelset. The buggy can then traverse along the rails in a pit beneath the train to an unloading area where the wheelset is raised. At this time, the old wheelset is exchanged for a new or refurbished one, and the process is reversed for the insertion of the new wheelset into the train.

Features

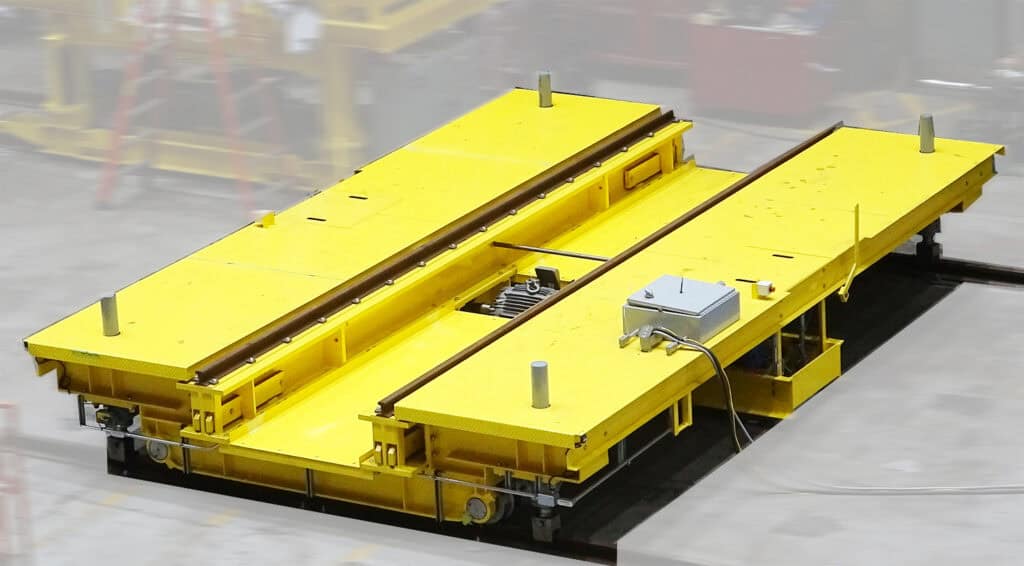

- Electrically powered to travel along tracks in a pit beneath the train.

- The top of the carriage incorporates rails.

- Built for use in a wet, outdoor environment.