Overview

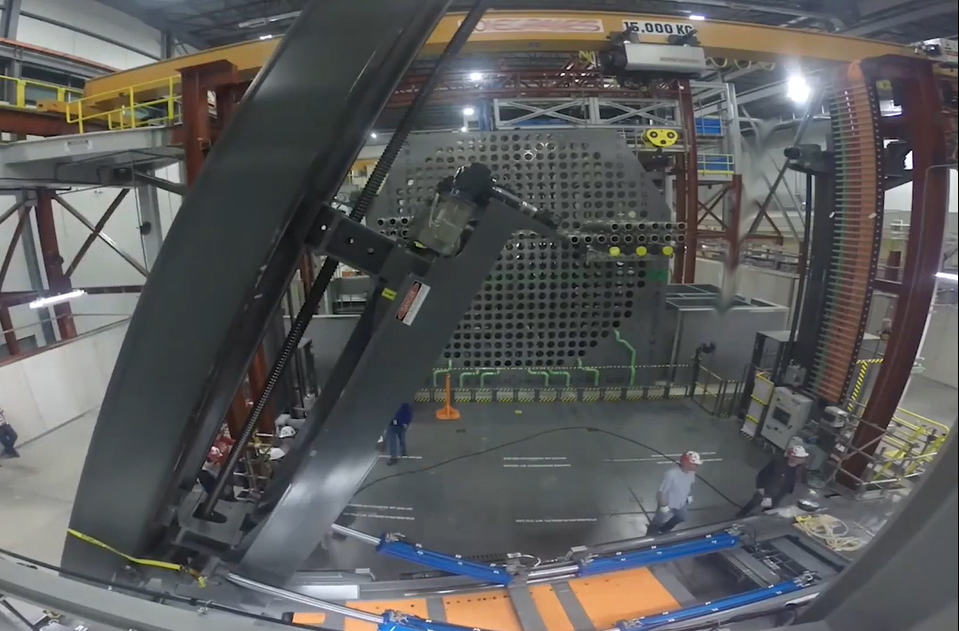

Retubing tool platform-column handler

Secured to a four-post lift, the retubing tooling platform-column handler performs the removal and replacement of reactor components. Otherwise known as the re-tube and feeder replacement phase. It accomplishes this task in part by utilizing its hydraulic tilt feature.

The tooling platform and column handler are operated remotely from the Re-tube Control Centre. The handler is also fitted with a hand-held pendant for an operator to operate the column handler from on top of the tooling platform.

What is the process of retubing?

The process of retubing a heat exchanger for the nuclear industry begins by removing damaged, corroded, or worn-out tubes. Next, the technicians will clean and prep tube sheets. With the help of the retubing tool platform, technicians will install the replacement tubes. Testing the heat exchanger follows, and then the evacuation, charge, and restart of the system.

When is retubing needed?

Nuclear power plants typically refuel every 18 to 24 months, often during the fall and spring seasons when electricity demand is lower.

Features

- Hand-held Pendant.

- 18,000 lb lift capacity.

- Limit switches.