Overview

Flexibility to alter the assembly floor is a new advancement in automated guided vehicles (AGV Systems) where in the past they were permanently tied to a physical track within the facility. Now, with advanced sensors – the unit uses laser guidance; moving along the pre-determined path set by tape or a painted line. This tape can be pulled up with little cost and re-positioned should the needs of the facility’s assembly line change. Compared to the costs associated with pulling up a track embedded into the concrete floor, Handling Specialty’s technologically superior AGV is a clear choice.

Features

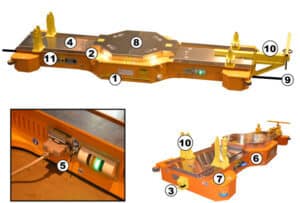

Automatic Guided Vehicle for Truck Outfitters Assembly Plant.

1. Emergency stop.

2. Flashing yellow safety lights.

3. Motion sensor.

4. 8 TPPL, 48 VDC voltage batteries.

5. Manual hand-operated control.

6. Brushless DC servo motor.

7. Capacity to carry 12,000 lbs (5,443 kg).

8. Laser guidance system programmed to follow the smart tape.

9. Programmable speeds via smart tape.

10. Custom Tooling.

11. Battery power meter.