Overview

Manually Guided Vehicles – What are They?

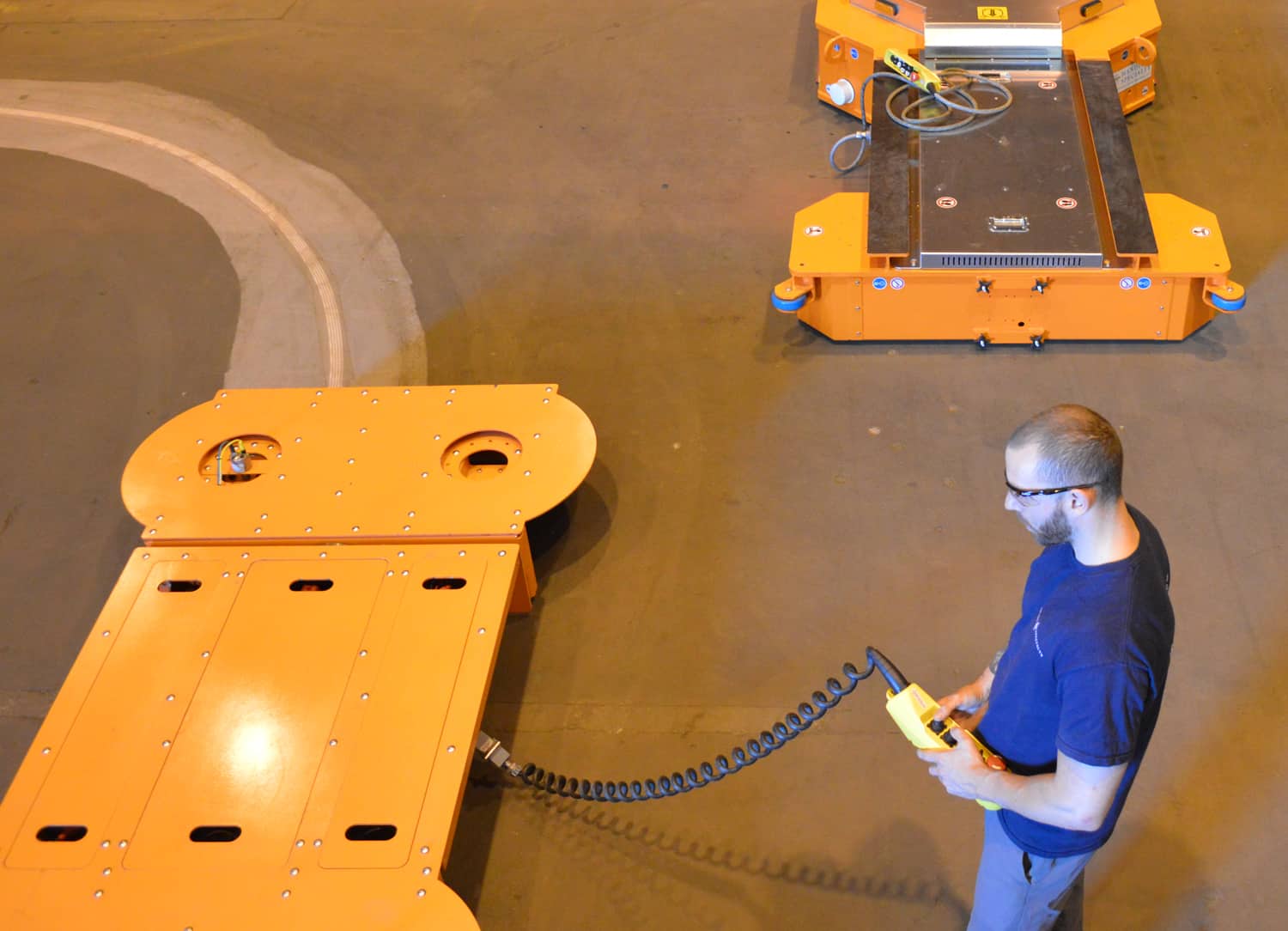

Manually guided vehicles (MGVs) are different than AGVs. Automatic Guided Vehicles are fully automated vehicles designed to follow a set path with specific instructions, whereas an MGV is a manually guided vehicle built to carry product through assembly, MRO, and manufacturing processes. These units, like an AGV, can be outfitted with custom tooling and even scissor lifts with rotating table tops if required.

Where do I use a Manually Guided Vehicle?

As mentioned above MGVs are perfect for MRO, assembly and manufacturing plants, but an MGV is also a useful tool in distribution warehouses fitting in places that forklifts cannot. Each manually guided vehicle can be custom-built to your business’s specific application needs. Size, weight capacity, tooling and steering are all customizable. MGVs operate in many industries across multiple applications. They create a more ergonomic solution than pulling product with tuggers or hand-pump trucks.

Features

Manually Guided Vehicle Steering

Steering the manually guided vehicle is done via a hand-held controller. These can be either wired to the unit or wireless, depending on the need. An MGV can perform forward/backward, side-to-side, diagonal (crabbing), and zero-radius turning. Again all of these functions will be under the control of the operator as they are required to move products and parts through an assembly line, MRO facility or manufacturing plant.

MGV Battery Charging

Every manually guided vehicle comes complete with a charging cord and batteries. These batteries are built for the industrial work an MGV is designed for and can vary in their charge times. Batteries come in many forms, and choosing what is best for your MGV application will be a consideration an engineer will arrive at.