Overview

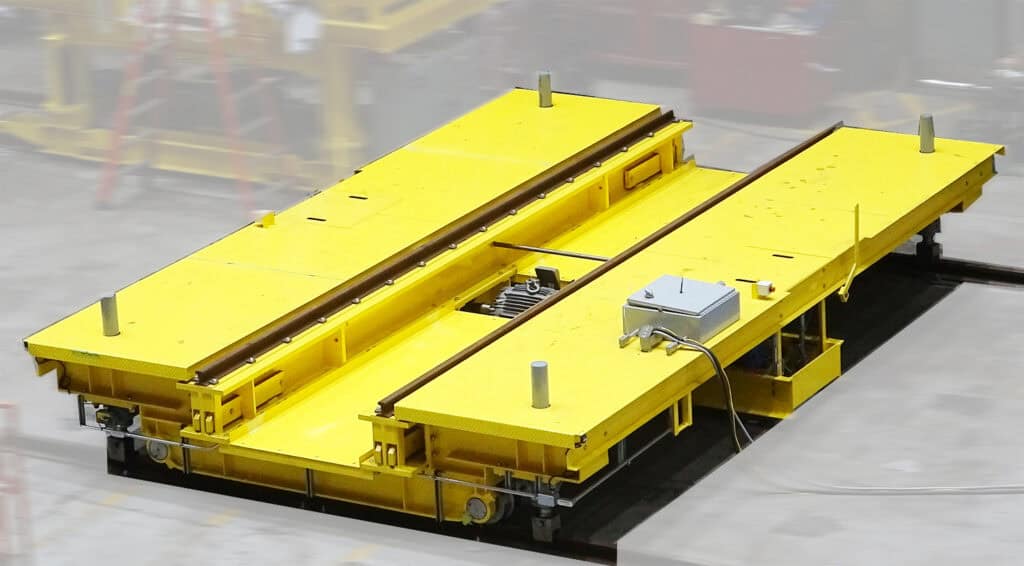

A large railroad maintenance facility in the United States required a 50-ton drop table to facilitate the changeout of traction motors on its locomotives. Handling Specialty custom engineered and designed a 50-ton drop table based on an original heavy-duty Whiting Corporation design.

Whiting pioneered the development of the drop table concept. Wheelset changeouts are fast, easy and efficient when you choose a drop table from Whiting. Available in single or double-axle configurations, Whiting works alongside you to build a system suited to your needs.

Whiting drop tables have many features that make them stand out above the rest, such as rugged body supports and girders, remote-operated consoles, a range of customized capacities, self-locking jack screws and optional release track tops.

Features

- Lifting capacity (low speed 2.5’ per minute) 108,000 lbs.

- Lifting capacity (high speed 5’ per minute) 23,000 lbs.

- Lowered height 39 5/8” from top of pit rail to mounting pad for service top.

- Traverse speed of trolley—high speed 30’ per minute.

- A radio remote control controls lifting and traverse functions.

- Lifting is done by Acme screw jacks and mechanical actuation.

- Screw threads on jacks are self-locking.