The global market for ergonomic equipment, like custom work positioners, is growing fast. This growth comes from the rising focus on workplace safety and efficiency in many industries. Work positioners are essential for improving industrial processes and creating better working environments.

The Role of Custom Work Positioners in Modern Industries

Custom work positioners play a crucial role in businesses’ quest to enhance productivity while ensuring the safety of their workforce. These tools, designed to be functional, flexible, and ergonomic, enable workers to move heavy items swiftly and accurately. This reduces the risk of injuries from heavy lifting and accelerates and refines tasks, thereby improving overall productivity.

Custom work positioners are revolutionizing industrial operations, from assembly lines to MRO facilities in diverse sectors such as Rail, Automotive, and Power Generation. Their unique ability to adapt to various workplace needs makes them indispensable for a wide range of tasks. Ultimately, they ensure a safer and more productive work environment, regardless of the industry.

Understanding the Functionality and Benefits of Work Positioners

Work positioners are designed to make work easier and safer. They help workers lift and move heavy loads with care and accuracy, which leads to better safety, efficiency, and productivity. Here are some main benefits:

- Precise Positioning: Work positioners, also known as AGVs, excel in placing materials exactly where they are needed, thereby reducing errors and enhancing the quality of work. This precision is a key benefit of these tools, contributing significantly to the overall efficiency of the operation.

- Ergonomic Material Handling: reduces the need to bend, lift, and reach, which helps lower the chance of musculoskeletal disorders.

- Improve Workplace Safety: Custom work positioners significantly reduce the risk of injuries by offering stability and support when handling materials. This emphasis on safety and protection makes the workplace a more secure environment for workers, fostering a sense of security and peace of mind.

Key Features of Custom Work Positioners Tailored for Industry Needs

One of the most significant benefits of custom work positioners is that they can be manufactured to fit the specific requirements of different industries and purposes. Unlike standard units, these positioners are built from the bottom up. They include important safety features, the correct sizes, weight limits, and functions that help them work well in each work setting.

Also, OEMs like Handling Specialty use the highest-quality materials to ensure they last and are reliable even in harsh industrial places. This focus on meeting specific user needs and safety features makes custom work positioners a wise investment. They help businesses work better while keeping their employees safe and happy.

Automotive Manufacturing and Assembly

The automotive industry has many complicated steps in assembling vehicles. Custom work positioners help with this. These positioners can change heights and angles. This allows workers to do their jobs better and with less physical strain. It lowers the risk of injuries, which helps create a safer and more ergonomic workplace, making it more productive.

Enhancing Precision and Safety in Automotive Production Lines

The car manufacturing industry is known for its complex assembly processes and high-quality requirements. It depends heavily on custom work positioners to boost precision and efficiency. These systems help accurately move heavy parts like engines, chassis, dashboards, and doors. This ensures assembly workers stay safe, the product remains in peak condition, and the final merchandise meets all standards.

Custom-designed positioners also help lower the risk of injuries linked to manual labor. These injuries can include back strains and issues from repetitive movements. By reducing physical strain and improving ergonomic positioning, these unique tools make workplaces safer and help increase productivity in auto production.

Aerospace and Aviation Sector

Aerospace manufacturing requires excellent precision and careful attention to detail. Custom work positioners are often used with other tools like jib cranes. They help with the complex assembly and care of aircraft parts. These solutions provide stability and better ergonomic positions, leading to higher quality standards, improved efficiencies, and a safer workplace.

Custom Solutions for Handling Complex Aerospace Components

The aircraft parts are complex, and putting them together requires great accuracy. Because of this, the aerospace and aviation fields depend on custom work positioners. These tools fit the unusual shapes and sizes found in this industry. They help technicians move and lock components easily.

Impact on Productivity and Worker Safety in Aviation Manufacturing

Before people widely used ergonomic equipment like custom work positioners, workers in the aviation manufacturing industry were at a higher risk of injuries. They had to lift heavy parts and work in uncomfortable positions, which caused musculoskeletal disorders and other health problems.

Now, manufacturers see a significant drop in work-related injuries thanks to custom positioners. These tools help reduce physical strain. They allow workers to move more naturally, which helps lower the chances of repetitive strain injuries. As a result, the work environment becomes safer and more productive, leading to less downtime and better overall efficiency.

Rail Maintenance Facilities

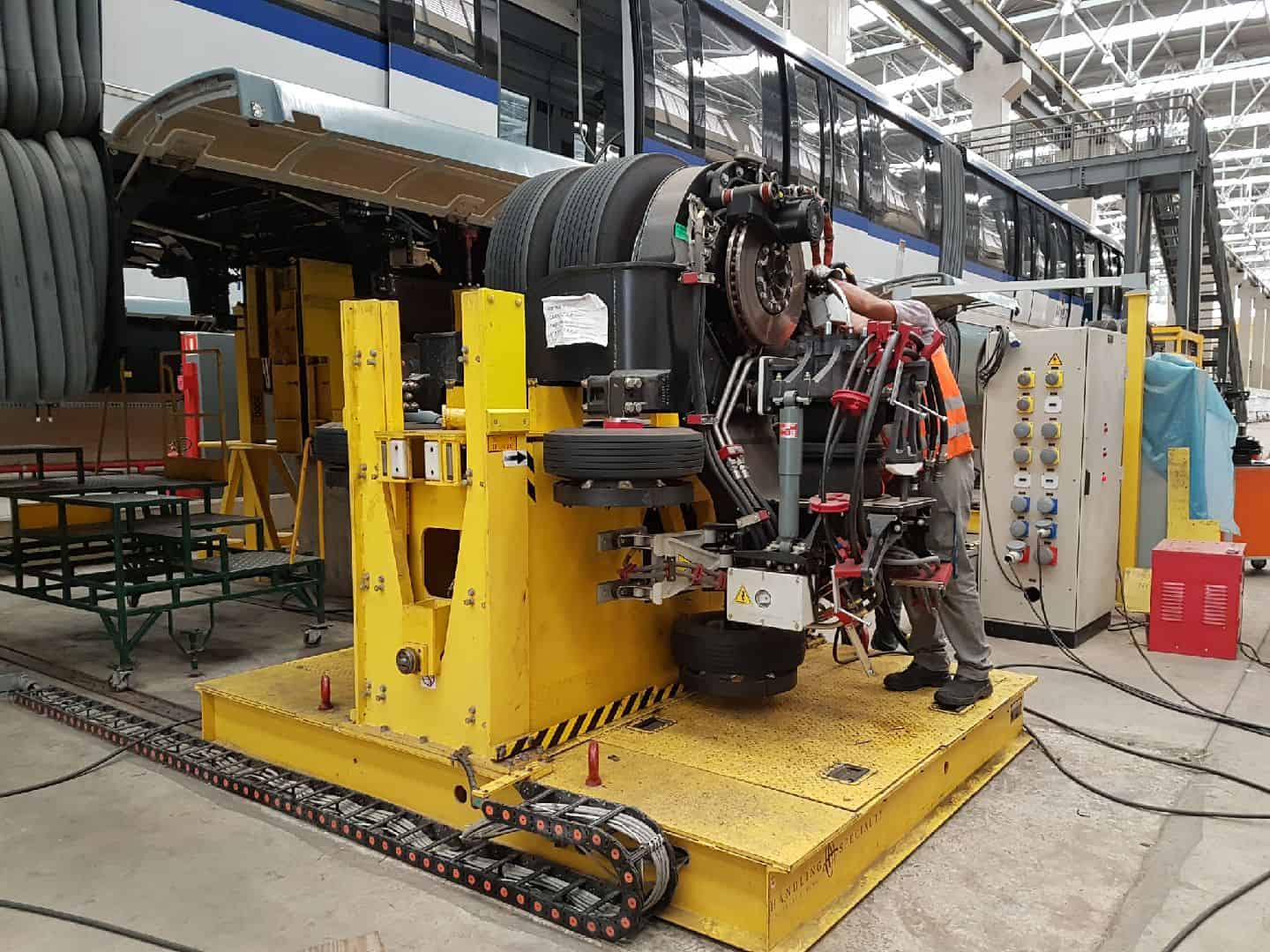

Custom work positioners help maintain high efficiency and safety in the Rail MRO industry. They rotate wheelsets and bogies for maintenance, inspection, and repair operations. Allowing a product to spin 360 degrees offers technicians unlimited access without any physical strain.

Addressing the Unique Challenges of the Rail & Transportation Sector

The rail & transportation MRO industries have unique challenges. Custom work positioners help meet these needs by providing unique solutions for specific MRO requirements. For example, positioners in these areas are engineered to hold and maneuver heavy parts for precise positioning on-site.

Also, worker safety is crucial. Ergonomic design is vital because repetitive tasks can cause musculoskeletal disorders. Custom work positioners are designed to keep users comfortable and reduce physical strain, helping create a healthier and more productive workplace for rail workers.

Examples of Custom Work Positioners in Rail Operations

Rail & Transportation MRO needs to handle important parts carefully. Custom work positioners help keep products safe and protect workers. Here are some examples:

- Rotating workstations for maneuvering wheelsets and bogies during MRO operations and inspections.

- Monorail Bogie workstations are designed specifically for the light rail/monorail industry. They allow the customer to drastically reduce the time needed for bogie maintenance, thus allowing the monorail to return more quickly to revenue-generating activities.

These examples of efficient material handling show how custom positioners fit the unique customer requirements in the rail industry.

Conclusion

In conclusion, custom work positioners are essential for improving efficiency, precision, and safety in industries like automotive, aerospace, Rail & Transportation, and many more. These solutions are made to fit specific needs, which helps boost productivity and keep workers safe. Examples from different industries show how custom work positioners can make operations better and help with complex tasks. By using new positioning technologies from Handling Specialty, industries can make processes smoother, improve product quality, and maintain high safety and efficiency standards in their work.

Frequently Asked Questions

What Are the Main Advantages of Using Custom Work Positioners?

The rise in the use of custom work positioners is due to their ability to safely and efficiently lift and maneuver heavy loads with precision. Their ergonomic design helps keep workers safe, reducing the risk of injuries and leading to a more productive workforce.

How Do Custom Work Positioners Contribute to Workplace Safety?

Custom work positioners have safety features like emergency stops and overload protection. They also have ergonomic designs, which help lower the risk of musculoskeletal disorders. This makes the workplace safer and helps prevent accidents and injuries.