What are the advantages of using 4-post electromechanical lifting systems?

4-Post electromechanical lifting systems offer superior stability, versatility, and ease of use. They provide secure lifting for heavy loads, precise positioning control, adaptability for various industries like automotive, power generation, and aerospace, and increased safety features compared to traditional lifting systems.

Introduction

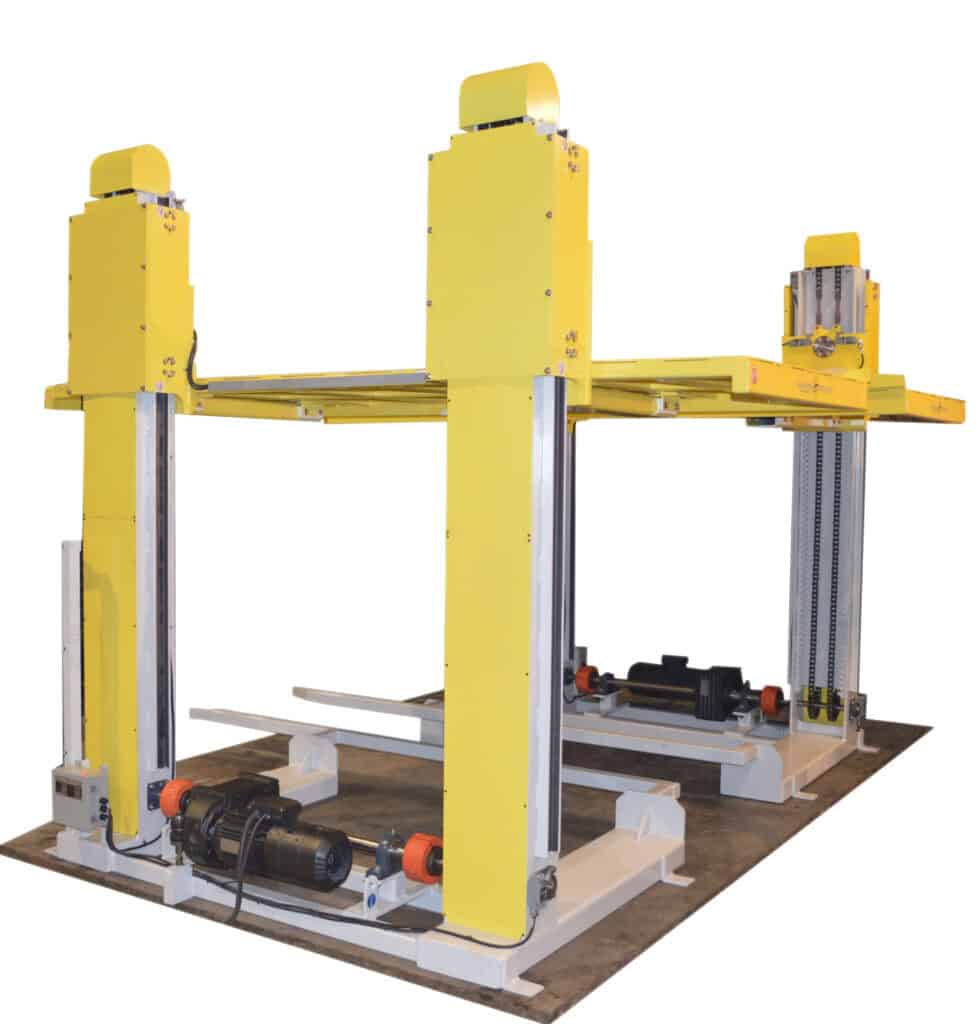

in an assembly, MRO, manufacturing, or testing facility, 4-Post Electromechanical Systems are highly prized lifting solutions that offer efficient and safe handling of heavy machinery. These systems are characterized by their electromechanical operation, which combines the benefits of both electrical and mechanical components.

Unlike traditional lifting systems that rely solely on hydraulic or mechanical mechanisms, 4-Post Electromechanical Systems utilize a combination of motors, line shafting, and bevel gearboxes to ensure a balanced load on motors regardless of the load’s position. This design eliminates the need for frequent adjustments during operation, resulting in smoother running and increased safety.

Understanding 4-Post Electromechanical Systems

Designed to ensure the safe and efficient lifting of heavy equipment, a 4-Post Electromechanical system consists of four columns, each equipped with a motor and a set of lifting screws, cables, or chains. The motors are interconnected mechanically by line shafting and bevel gearboxes in an oil bath, enabling synchronized lift platform movement.

One of the key advantages of these systems is their ability to maintain a perfect level of the platforms regardless of the load’s position. This ensures the load is evenly distributed and prevents any imbalance or shifting during the lifting process. The use of safety nuts and automatic lubrication further enhances the smooth running of the system.

Safety nuts are responsible for providing support and stability to the lifted load. In the event of a failure in the main nut assembly, a safety switch is activated, automatically stopping the lift’s motion. This additional safety feature prevents accidents and potential damage to the lift and the load being lifted and positioned.

The Basics of 4-Post Lift Technology

The safety nut assembly is a vital component of 4-Post Electromechanical Systems. It provides support and stability to the lifted load. The assembly consists of main and safety nuts that work harmoniously to ensure the platforms’ safe lifting and lowering.

Positive lubrication is essential to ensure smooth running and longevity of the lift. 4-Post Electromechanical Systems feature automatic lubrication of the main and safety nuts and spindles. This is achieved by a plunger pump located in each column, which delivers lubrication to the necessary components every time the lift is raised. The positive lubrication provided by the plunger pump ensures that the lift operates smoothly and minimizes wear and tear on the moving parts.

Benefits of Using 4-Post Electromechanical Systems

Safety, efficiency, and versatility

These systems are designed to enhance the overall safety of the lifting operation and provide a smooth and reliable lifting experience. Automatic lubrication and safety features such as mechanical safety stops and limit switches ensure the safety of the lift and the elevated loads. Additionally, these systems offer increased efficiency in load handling, making them ideal for a wide range of applications in multiple industries.

Enhanced Safety Features

4-Post Electromechanical Systems are equipped with various safety features to ensure the safe operation of the lift. These features include:

- Mechanical safety stops: These stops prevent the lift from going beyond its intended lifting height, ensuring that the loads being lifted are secure and stable.

- Limit switches: These switches prevent the lift from lowering beyond a certain point, preventing accidents or damage to the lift and the loads.

- Safety nuts: The safety nuts provide additional support and stability to the lifted load, preventing any potential imbalance or shifting during the lifting process.

These safety features work together to create a secure and reliable lifting experience, minimizing the risk of accidents and ensuring the safety of both the lift operators and the loads being lifted. Additional safety features, such as audible and visual alarms and cages to keep others out of the multi-post lift‘s working area when in operation, can be purchased to meet every facility’s needs.

Design and Installation Considerations

Certain factors need to be considered when designing and installing a 4-Post Electromechanical System to ensure optimal performance and functionality. These considerations include the facility’s specific assembly, MRO, and manufacturing requirements, installation space requirements, and electrical requirements for the lift’s smooth operation.

Additionally, any custom tooling needed to fulfill a customer’s requirements for precise load positioning, like rotating and tilting features, should be discussed at length with the design/build firm’s technical sales and engineering departments. Improving the handling of the load will include offering ergonomic positioning so that the technicians have 360-degree access to the load for maintenance, repair, assembly, testing, and inspection activities.

Applications of 4-Post Electromechanical Systems

4-Post Electromechanical Systems have a wide range of applications in various industries. These systems are commonly used in the assembly industry for tasks such as part maintenance, repair, and inspection. They are also utilized in heavy machinery and equipment industries for tasks involving the lifting and handling of large and heavy loads, such as aerospace engines and energy industry turbines.

Applications in Heavy Machinery and Equipment

4-Post Electromechanical Lift Systems find applications in industries such as automotive, aerospace, advanced manufacturing, energy, and rail & transportation. These systems are designed to handle large and heavy loads, making them suitable for tasks such as:

- Lifting heavy machinery and equipment: 4-Post Electromechanical Systems provide a reliable and efficient way to lift heavy machinery, parts, and equipment. The system’s design ensures the safe and secure lifting of heavy loads.

- Line shafting applications: Line shafting is commonly used in industries that require the synchronization of multiple lifting platforms. 4-Post Electromechanical Systems can be configured with line shafting, allowing for the simultaneous lifting of multiple platforms and reducing the time and effort required for lifting operations.

- Tilting applications allow one-half of the multi-post lift to raise or lower while the other remains in a static position, allowing for a portion of the load to be worked on.

- Rotating applications: with specialized tooling, any load can be rotated to ensure 360-degree access to the load for assembly, inspection, or MRO operations.

Maintenance and Troubleshooting

Routine maintenance ensures that the system functions optimally and prevents potential issues. Troubleshooting strategies, as laid out by your design/build firm, help identify and resolve any problems that may arise during the lift’s operation.

Routine Maintenance Tips

Regular maintenance is required to ensure the long life and reliable performance of your 4-Post Electromechanical Systems. Here are some routine maintenance tips:

- Check and tighten the safety nut assembly for proper support and stability during lifting operations.

- Regularly inspect and lubricate the main, safety nuts, and spindles to ensure smooth running and minimize wear and tear.

- Monitor the lift’s overall condition, including the sensors, limit switches, e-stop, motors, line shafting, and bevel gearboxes, and address any issues promptly.

- Follow the manufacturer’s guidelines for maintenance intervals and recommended lubricants to ensure optimal performance and long lift life.

Innovations in 4-Post Electromechanical Systems

4-Post Electromechanical Systems are continuously evolving and improving with recent technological advancements. These innovations aim to enhance these lifting solutions’ safety, efficiency, and functionality.

One recent technological advancement in 4-Post Electromechanical Systems is the use of IIoT or the Industrial Internet of Things. This refers to smart monitoring of your multi-post lift’s systems via sensors that will detect wear and alert the manufacturer and the customer of potential problems before they can cause downtime in your facility.

The trend in electromechanical lifting solutions is expected to focus on further advancements in efficiency and automation. Companies like Handling Specialty Manufacturing Ltd., a leading manufacturer of lifting systems worldwide, are investing in research and development to introduce new features and accessories that enhance the overall performance and functionality of 4-Post Electromechanical Systems.

Choosing the Right 4-Post Electromechanical System

When choosing a 4-Post Electromechanical System, several factors need to be considered to ensure the system meets the application’s specific requirements. These factors include the weight capacity of the lift, the load position during lifting, and the specific needs of the industry or facility. Tilting and rotation of the load may be required to offer ergonomics for the technicians working with the load.

Comparing Different Models and Brands

When comparing different models and brands of 4-Post Electromechanical Systems, it is essential to consider the reputation and reliability of the manufacturer. Companies like Handling Specialty, known for their expertise in lifting solutions, offer a wide range of customization to suit different applications. It is also essential to consider the availability of additional accessories, such as rotators and tilters, which can enhance the functionality and versatility of the system. By carefully comparing the features, specifications, and extra accessories offered by different brands, it is possible to choose the right 4-Post Electromechanical System that meets the specific requirements of your application.

Case Studies

Case studies provide real-world examples of the benefits and applications of 4-Post Electromechanical Systems in various industries.

Success Stories in the Aerospace Sector

Lagged to the customer’s floor, two 4-post Prep-to-Ship workstations will prepare aero engines for shipment in the client’s mixed-model building. They run three cycles per day, 365 days per year, and are fitted with 5-ton cranes and hand-held spotlights. These four-post workstations offer exceptional functionality.

Impact on Productivity and Efficiency in Energy Industry

Handling Specialty completed a 15 and 30 30-ton engine Rollover Station for the energy industry, placed in a state-of-the-art manufacturing facility. Handling Specialty also provided installation and commissioning of these products. The Engine Rollover Stations will position reciprocating engines during manufacturing operations. The rollover feature and the side-to-side slide operation allow for ergonomic work positioning for operators, assemblers and maintenance workers.

What We’ve Learned About 4-Post Electromechanical Systems

Innovative 4-Post Electromechanical Systems offer enhanced safety, efficiency, and versatility in various industries. With advanced technological features and future-proof designs, these systems bring a new level of performance to load handling and equipment maintenance. Understanding the key components, benefits, and applications of these systems is crucial for optimized usage. By considering factors like space requirements, electrical needs, and maintenance strategies, businesses can make informed decisions on selecting the right system for their specific requirements. As electromechanical lifting solutions evolve, staying updated on recent advancements and future trends ensures that businesses stay ahead in productivity and efficiency.

Frequently Asked Questions

What are the advantages of using 4-post electromechanical lifting systems?

4-Post Electromechanical Lifting Systems offer several advantages, including enhanced safety features like safety switches and mechanical safety stops. These systems also ensure a perfect level of the platforms, regardless of the load’s position, providing stability and ease of use. The precise control and reliable performance of these systems make them ideal for a wide range of lifting & positioning applications.

How does a 4-post electromechanical lifting system differ from traditional lifting systems?

One key difference between 4-Post Electromechanical Lifting Systems and traditional lifting systems is that safety nuts are used instead of load-bearing chains. This improves the lift’s stability and reliability. Additionally, the use of bevel gearboxes in an oil bath ensures smoother and more synchronized movement of the lift platforms, reducing the risk of imbalance or jerky motions.

What are the key features to consider when choosing a 4-post electromechanical lifting system?

When choosing a 4-Post Electromechanical Lifting System, key features include motor protection mechanisms, limit switches to prevent overextending, customization, and the lift’s weight capacity.