Overview

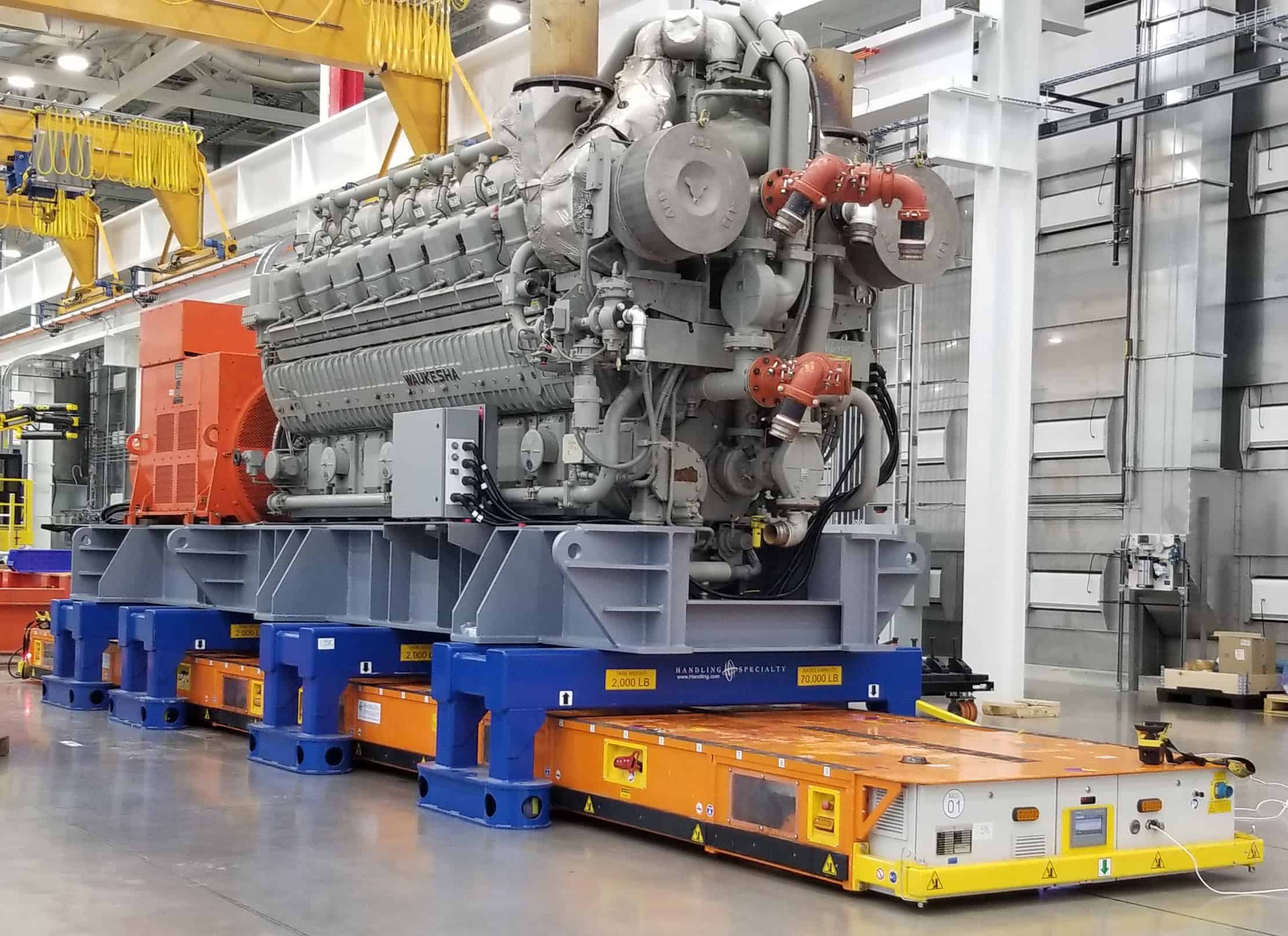

Using two 100,000 lb. AGVs in tandem, a customer can place up to 200,000 lbs. on the unit to be moved through the assembly line. Engineered and manufactured to lift and precisely position engines for assembly and maintenance purposes, Handling Specialty’s 200,000 lb. Manually Guided Vehicles employ modular traction/steering drives that are bolted to a fabricated steel frame. The traction/steering modules simplify the operation and maintenance of the engine transporters.

The Traction/Steering modules provide the force to move the MGV. Each module consists of two polyurethane wheels, each driven by a servo brake motor. These servo motors provide differential speed steering control to the module angle and provide traction. Each module is equipped with an absolute encoder to monitor the angle of the module.

All models feature traditional steering as well as crab steering capabilities. The engine transporters also feature Zero Turn Radius (ZTR) steering, which allows the transporter to turn about its center. All of these steering modes are available in both unloaded and loaded conditions offering maximum flexibility of use.

All models have an e-stop button on the corners of the mainframe as well as amber strobe lights and audible signals that indicate the transporter is going to start moving and is in motion. Additional safety features like sensors help avoid collisions with people and products.

The 200,000 lb. models feature an integrated hydraulic lift function that allows the transporter to pick up engines with the assistance of a specially designed tooling fixture.