Overview

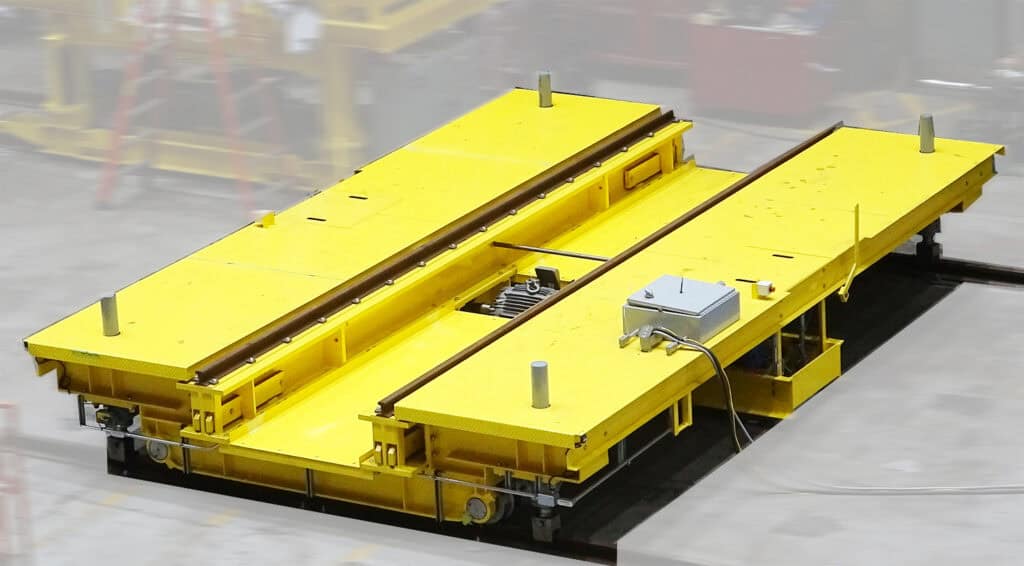

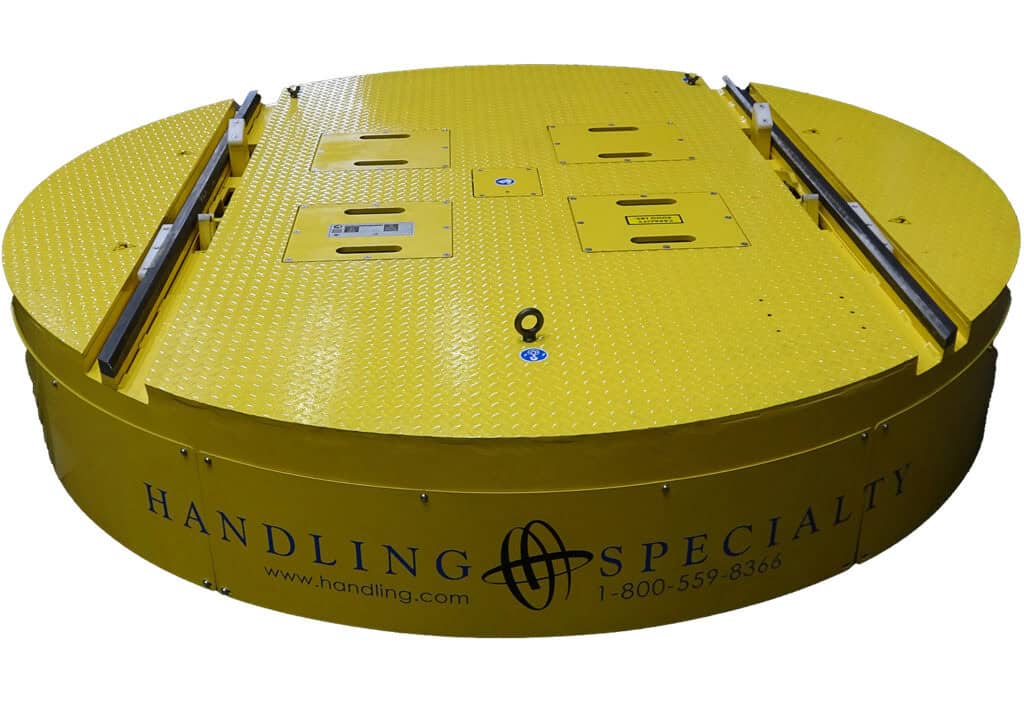

Handling Specialty custom designed and manufactured a mechanically-actuated shim table for a Canadian locomotive maintenance facility. The table was used in the shimming process, which adjusts wheel diameter differentials.

After completing the trueing process, where wheels are ground back to a uniform roundness, the locomotive positions the wheels over the shim table. The table then lifts the locomotive 1” to relieve the downward forces on the traction motor. This permits rail personnel to place shims which drive the wheels down to meet the tracks evenly.

Features

- Includes an operator control unit and a hand pendant.

- Two controls are interlocked, so operations can only be performed from one control at a time.